It is very common that a customer will visit us wanting 1 or 2 shirts to be printed. As sad as it makes us, we have no choice but to turn them away and recommend direct to garment printing. Here’s why. At Twin City Tees we use a process called screen printing, which requires that we implement a 12 shirt minimum order. Why the minimum?

When screen printing, each artwork color needs to be placed on a separate layer, images must be burned onto mesh screens, and then colored ink is pressed through the screens to make a print. Each color requires a different screen. The process of preparing artwork, burning a screen(s), and setting up the press, takes a lot of time. The setup time and cost of preparing a job doesn’t change between 1 shirt and 100. For this reason screen printing is not cost effective for very small orders.

Screens Ready For Artwork Burning

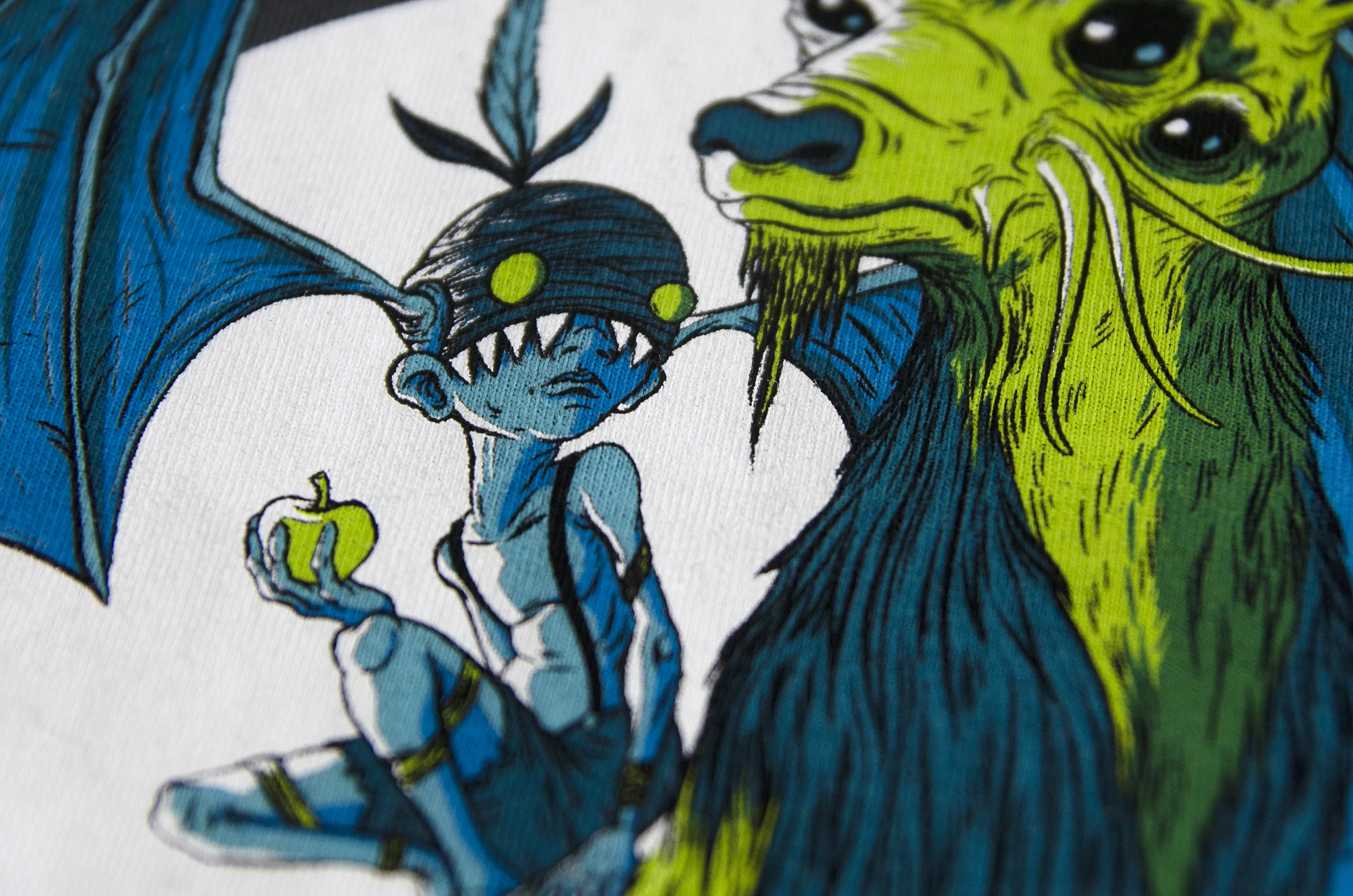

Screen Printed Image Close Up | 5 Colors

Then why direct to garment printing for small orders?

Direct to garment printing is basically an inkjet printer that lays dots of ink down onto a garment. Setup is minimal and, therefore, cost effective on very small orders.

Quality and Details | Screen Printing vs Direct to Garment

Screen Printing

At Twin City Tees, we can achieve extremely high detailed results while printing multiple colors using screen printing. We use the highest quality ink in the industry and, therefore, the print will last.

Tight Details Achieved Using Screen Printing

Direct To Garment

Quality with a direct to garment printer depends greatly on the printer that is being used. A direct to garment printer can vary in price from $1,000 up to millions of dollars. Because of this, just like with screen printing, it is important to do some research into the print shop you choose to print with. Ask to see examples if you are wary and require the highest quality possible.

Cost | Screen Printing vs Direct to Garment

Screen Printing

As mentioned above, it is more cost efficient to print orders above 12 garments using screen printing. While setup and artwork prep take a long time, once on press, shirts can be printed at 600-1200 shirts per hour. For this reason, at Twin City Tees, we offer many price breaks as your order number increases.

Direct to Garment

Small orders less than 12 garments are more efficiently printed with a direct to garment printer due to lack of setup time. With direct to garment printing, the process is much slower, and therefore the cost will be higher for larger jobs.

So there you have it, both screen printing and direct to garment printing are viable options when having shirts printed. It really comes down to the number of shirts you would like to have printed and what quality and price you are looking for.

We are happy to give you a Quote for any orders over 12 garments.